Hybrid Tugs shipyard

VISION AND GOALS

TAKING UP PROJECT

The project will be undertaken by the newly established company Pro Marine Yachts S.A., the subcontracting by Pro Marine Shipyards and the management of the project by Pro Marine Shipmanagement & Co SA.

The above companies, all newly established, with the main shareholder and founder with long experience in the industry Mr. Michalis Spanopoulos, who remains to be one of the two equal owners of the Spanopoulos Group.

The group cooperates with the biggest companies in the world that use tugs to serve their fleet.

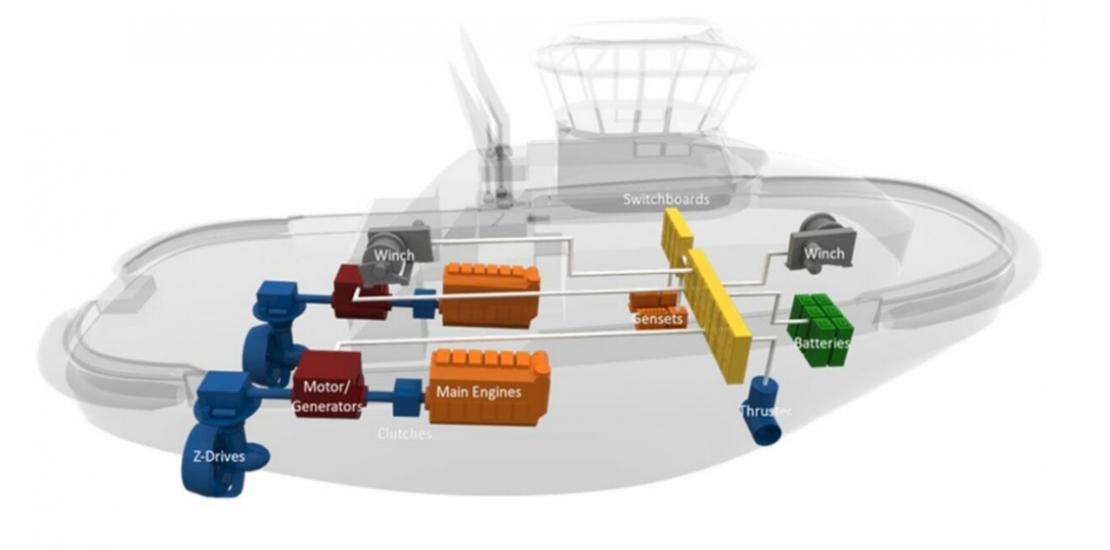

The emission of greenhouse gases are a problem which is treated seriously nowadays. Especially inland waterway vessels have an enormous potential for optimization hence to their relatively aged engine technology. This is caused due to the persistence of ship structure as well as the drive line, which allow a very long life span of these vessels. Because of the right of continuance, they often don’t meet reasonable emission values. Supplementary in metropolitan areas like Piraeus, all the Mediterranean ports, Berlin, Hamburg or the Rhein/Ruhr area, this old engine technology is a stress for human health. In these areas, subject like particulate matter and noise emissions getting more and more important. Therefore, the department “Design and Operation of ProMarine Innovations” (Athens) designs a pusher tug for the capital region Athens – Piraeus with an innovative power unit and energy concept. Regional transports shall be carried out with electrical power from battery stacks. Supraregional transports will be realized by the support of fuel cells as range extender. Using renewable energy for the battery charging, this ship will operate as a fully “Zero Emission Ship”. All the advantages of hybrid power management will combined to ensure eco-friendly, reliable and economic carriage of freight. The first challenge of such an innovative design is the setting of specifications, which shall be done as detailed as possible.

Hybrid propulsion has many positive effects on operational costs. High plant flexibility leads to higher optimized engine efficiency, because the combustion engines can run for longer with high and constant loading. By reducing their operating hours, we also cut maintenance costs and extend engine life.

In terms of capital expense, the falling prices of batteries and associated technology are lowering the overall cost of a hybrid tugboat towards the level of a conventional version