Shipbuilding of 18.6-meter Multi-Role Interceptor PROM 1860 MRI from PROMARINE YACHTS SA on behalf of PROMARINE INNOVATIONS

The perfect outcome of Swedish and Italian marine engineering, The PROM 1860 MRI represents a new breed of interceptors that is faster, stronger, wider, and more stable.

Combining great talents in the fields of design and engineering, this vessel is a true showcase of what the latest technologies on the market can do with astonishing capabilities that include propulsion versatility, hybrid construction material, long patrol range, true offshore capabilities, and limited weight distribution sensitivity.

The design and development are only part of the equation, as the tooling is equally important in order to guarantee that the end product accurately reflects the design and delivers consistent and long-term performance.

Once the design and tooling were completed, another big factor became the component partners, as making a fast boat is easy, but making a boat that is fast every day is a completely different story, accordingly careful consideration was taken when choosing the components starting from the composites all the way to every wire, nut, and bolt.

PROM 1860 MRI Main Particulars

PROM 1860 MRI Main Particulars

The Boat was developed to be a powerful offshore interceptor boat with some extended range capabilities and clear yet advanced parameters which included the following;

© Ability to perform in sea state five conditions and operate in sea state six.

© Ability to sustain a cruising speed of more than 40 Knots and achieve over 60 knots in sprint

mode.

© Have a patrolling range of more than 700 nautical miles.

© Not be overly sensitive to weight distribution.

© Maintain good visibility in all conditions with minimal bow lift during transitioning from

displacement to plaining speeds.

© Be self-bailing and unsinkable.

© Integrate sophisticated control and communications equipment.

To Achieve the required parameters, the development process has been split into five categories:

Hull, deck and superstructure, Propulsion and control, Navigation and communication, and production tooling.

The hull design

The hull was developed to achieve class-leading performance targets with the overall size dictated by the operational conditions.

The basic hull design is a two-stepped hull with an integrated bracket of 18.6 Meter molded length and 4.2-meter beam, the steps provide a reduced surface when on the plane which leads to better efficiencies in terms of speed and fuel economy, the reduced surface also improves comfort as pounding is minimized.

The lifting strakes and spray rails have been developed to be a significant contributor to adding lift and minimizing spray as well as to allow the boat to track straight even in the toughest conditions, To further enhance the capabilities of the hull, every unutilized cavity in the hull is filled with close cell foam for added buoyancy and to prevent unintended flooding making the boat unsinkable.

While the hull can operate with inboard engines combined with either stern or surface drives, the design was optimized to allow for the installation of up to five outboards, this decision was further validated by the introduction of the 450, 500, and 600 reliable

outboard engines. And the net result is a boat that can achieve speeds of more than 60 knots.

Cabin & Super Structure

Considering the overall measurements of the vessel, a special design criterion was put in place to optimize the usability. These criteria included the general requirements such as:

© Head clearance no less than 2 meters in any area of the boat

©Passage width clearance no less than 55 CM in all areas

©Gunwale height is between .9 and.1 meter.

© Future-proofing by creating generous cable and hose conduits.

© Possibility to have a closed climate control cabin.

© Allow for multiple toilet compartments

© possibility to add ballistic protection panels

© possibility to add seating for up to 20 troops

© Allow for a brig or detention compartment

© allow for a galley that might be needed for

extended missions

© Allow extra power that may be needed for automated weapons platforms

Based on the above parameters the deck was developed with three main sections, The aft area totaling 12 square meters of open space. The aft deck also features access to the bilge area and engine room for service accessibility, as well as access to the generator, Air conditioning systems, or the Gyro stabilizer if installed. The aft area also accommodates up to 16 scuba tanks.

The second area is the wheel house which consists of six sections that can

accommodate a crew of six, each with their dedicated screen and controls as needed, and the elevated helmsman and navigator stations that are designed with the best ergonomics possible allowing for extended trips to be piloted with minimal fatigue, The helm concept also maintains a clean yet sophisticated approach relying on full integration between propulsion, communication, and navigation, with dual redundancy built in the equipment.

The wheelhouse can feature up to 12 screens that can access all the vessel’s systems.

The second is the front cabin which is configured to accommodate 16 folding seats with a suspension system, a toilet compartment, and space for a detention section if needed, this area also features access to the front-mounted weapon, remote or otherwise, as well as, a retracting ladder with direct access to the front deck.

Propulsion and control

As mentioned above, the vessel is designed to accept a wide range of propulsion systems including Petrol or diesel inboards combined with stern drives up to 400 HP and surface drives up to 1000 HP, and outboard engines up to 600 HP gasoline in petrol form and 300 HP is diesel form.

Based on the operational requirement, a quad installation of 600 HP Marine Diesel V8s combined with surface drives has been selected due to their lightweight, reliability, power, and efficiency. The Engines are mated to surface drives via a transmission supplied by ZF, the surface drives offer unmatched performance efficiency which, combined with the engines’ power and lightweight, offer the best performance for this application.

The Engine

The Marinediesel VGT600 V8 6.6L is the world’s most powerful and compact lightweight diesel engine that is designed to suit all commercial and governmental high-speed applications.

Engine type

Engine duty rating

Crankshaft power [hp(kW)]

Rpm@full load

Cylinders

Displacement [L]

Bore [mm] % % %

Stroke [mm]

Compression ratio

Electronic engine diagnostic

Max. torque, NM @ 2100 rpm

Dry Weight Bobtail [kg]

Injection system

Firing order

V8

C10 – HSC – High speed craft

600 (436)

3200

8

6,6

103

98

16:1

YES

1300

530

Bosch common rail

1-2-7-8-4-5-6-3

The Transmission

Considering the high-speed requirement it was crucial to select a durable and light transmission, accordingly, the ZF 280 Vertical offset, direct mount marine transmission

has been selected for this application on the following basis:

Description

© Suitable for high-performance applications

© Reverse reduction marine transmission with hydraulically actuated multi-disc

clutches.

© Robust design also withstands continuous duty in workboat applications.

© Compatible with all types of engines and propulsion systems, including

surfacepiercing propellers.

© Fully works tested, reliable and simple to install.

© Design, manufacture, and quality control standards comply with ISO 9001.

© 3 shaft, reverse reduction transmission with hydraulic clutch mounted on the input shaft and another one mounted on the reverse shaft. Input drive on the opposite side to output drive.

Features

© Lightweight and robust aluminum alloy casing (sea water resistant).

© Case hardened and precisely ground gear teeth for long life and smooth running.

© Output shaft thrust bearing designed to take maximum propeller thrust astern and ahead.

© Smooth and reliable hydraulic shifting with control lever for attachment of push-pull cable.

© Suitable for multiple engine installations (same ratio and torque capacity in ahead or astern mode).

The Drive

To achieve the required high performance reliably, we have chosen to use a steerable and trimmable surface drive system that not only offers spectacular performance but also adds shallow water capabilities to the already very capable vessel.

The entire power train system of engine, transmission, and drive weighs 798 KG making the package one of the most competitive interns of power-to-weight ratio.

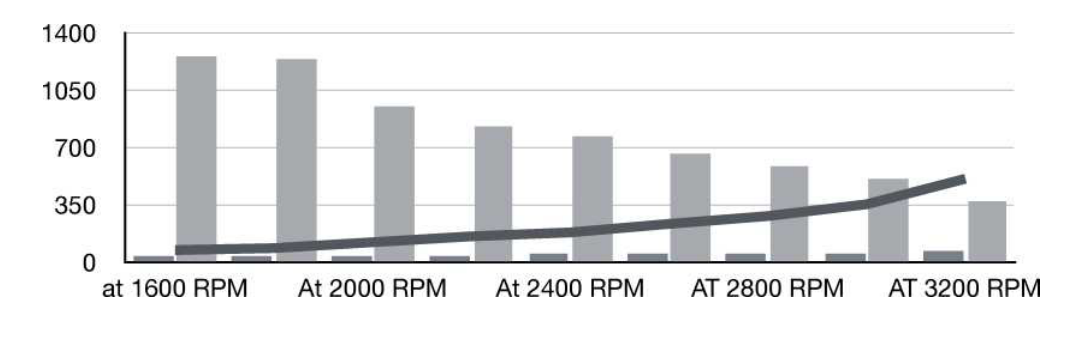

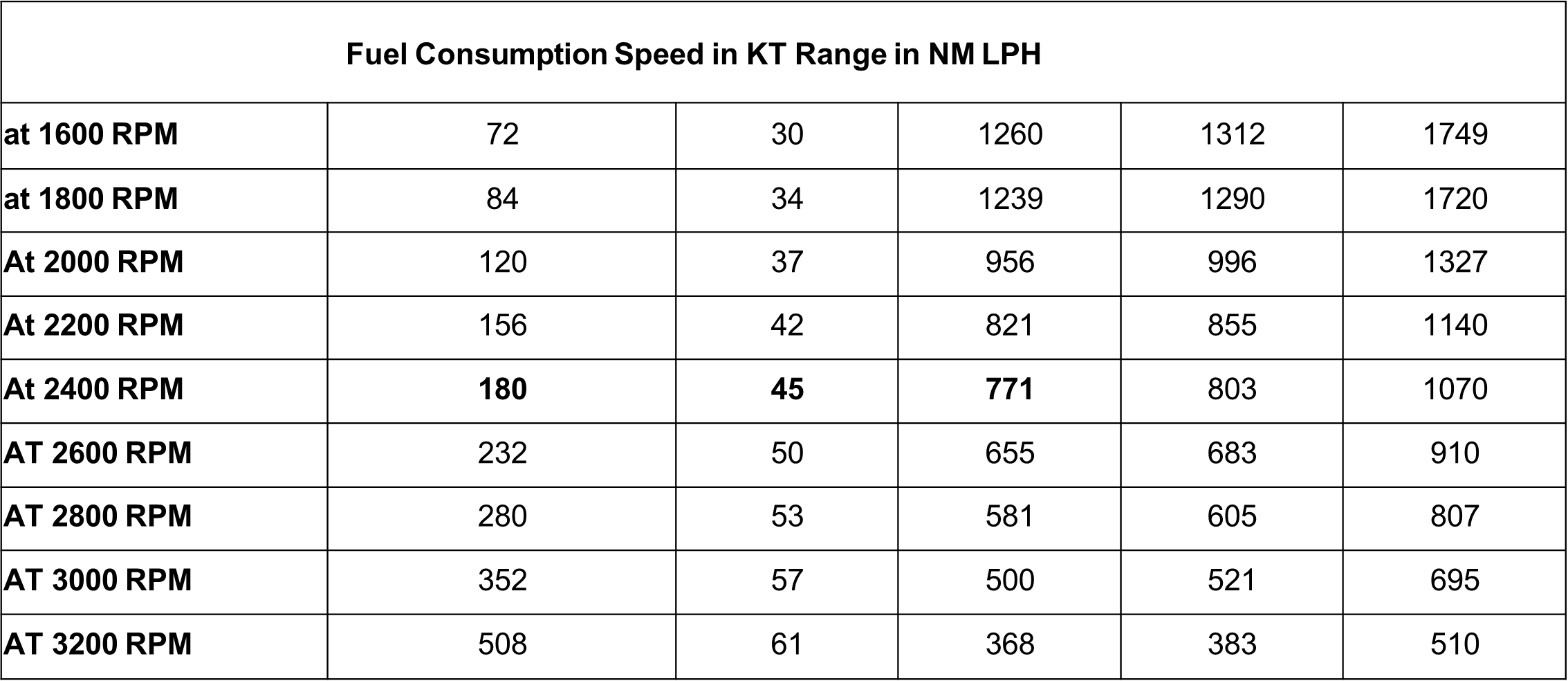

— Fuel Consumption LPH | Speed in KT | Range in NM

Navigation & communication

In general, We limit our choices for such high-performance vessels to one of two electronics suppliers, Raymarine and Simrad. For this particular application, we have chosen to go with Raymarine as it offers the best Camera, Chart-plotter, Depth sounder, Radar, VHF, loud Hailer, and AIS combination with seamless integration. Their lighthouse operating system is also the industry benchmark and remains easy and logical to use.

For the Multi-function displays, we have chosen the hybrid touch system in the form of Axion 12.1 Pro, with a total of 8 units installed on each boat.

For the Radar, we have chosen the award-winning solid-state open array radar the Cyclone 55 Watt with 72 Nm range.

The Raymarine Ray 73 will provide the functions of AIS, VHF Radio, and a loud hailer.

The system is further complemented with A TECH Security Systems camera as well as a night and day camera to be installed in the engine room.

Performance Figures at Light Weight Conditions

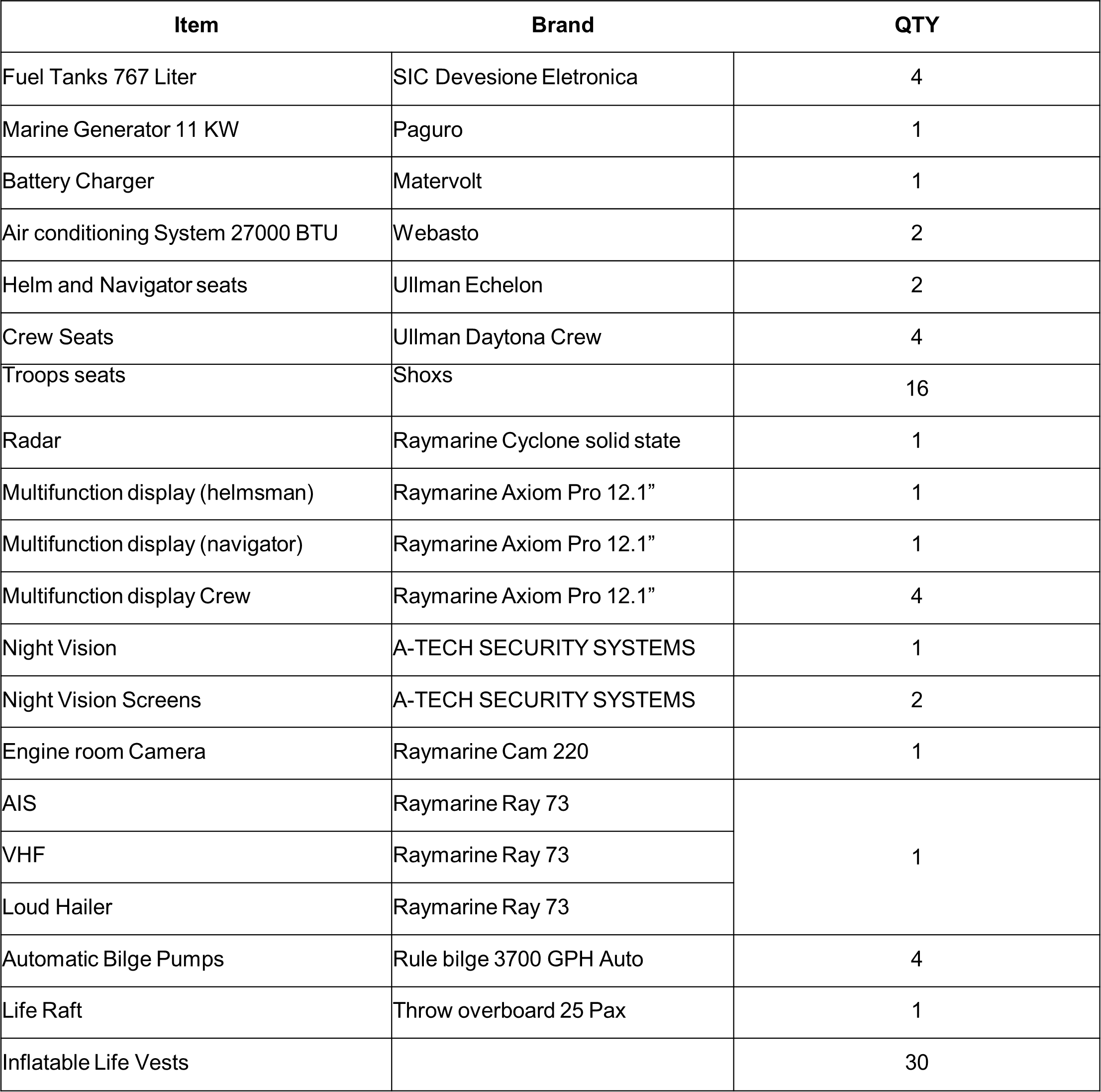

List Of Major Standard Items